ABOUT US

A third-generation family-owned textile company established in 1956. Focusing on natural fibres and circular manufacturing. Recognized for our 360-degree vision and perspective of what is happening around us, combined with decades of tradition, innovation, textile design & production.

A circular system is one in which products are designed, manufactured, used and handled so as to circulate within society for as long as possible, with maximum usability, minimum adverse environmental impacts, minimum waste generation, and with the most efficient use of water, energy and other resources throughout their lifecycles.

Collecting and sorting post-industrial waste from local garment factories, grounding these scraps back into fiber, to spin these once again into new yarns to weave and upcycle into our curated woven fabrics collection.

The process is chemical-free, dye-free, and uses minimal water and energy. We do not add any synthetic fibers (such as polyester, nylon, acrylic, etc), committed to creating products that are all 100% natural and compostable - circular.

The cottonseed and cotton lint, our own leftover material from our upcycling process, is passed on to coffee-growers, Finca San Jeronimo Miramar, to use as compost to cultivate specialty coffee in the highlands of Guatemala. Upcycling this waste back into production systems, making it a reusable and valuable resource, serving as food for new organisms.

More than a process, it is a goal that is ethical, economical, efficient and visionary, guiding us in changing our practices to emulate sustainable natural cycles, where all discarded materials are designed to become valuable resources for others to use. Our eco-industrial techniques have led us to reduce our carbon emissions, water, energy usage, and vastly minimize the consumption of new virgin raw material. Reusing discarded textiles that will allow for abundance and endless life cycles. Leading the way towards a sustainable and thriving industry, proudly operating under a circular economy, like the earth itself.

CIRCULAR TEXTILE SYSTEM

CIRCULARITY IS THE UNDERSTANDING THAT:

"Everything you make returns to Earth as either food or poison"

Slow Factory Foundation

IMPACT

CARBON FOOTPRINT

The apparel and textile industry accounts for 10% of global carbon emissions and remains the second largest industrial polluter, second only to oil. The industry’s immense footprint extends beyond the use of raw materials. In 2015, greenhouse gas (GHG) emissions from textiles production totalled 1.2 billion tonnes of CO2 equivalent, more than those of all international flights and maritime shipping combined.

WASTE GENERATION

A consumer today owns 300% more clothes than a generation ago, and on average wears clothing 7 times before getting rid of it. Fast fashion has created a business model based on the artificial creation of short term trends combined with clothing that doesn't last - what other industries call “planned obsolescence.” This cheap mentality has come devastatingly high costs for the environment and the people making clothing. 150 billion garments are produced annually, enough to provide 20 new garments to every person on the planet, every year. 26 billion lbs. of textiles are trashed each year and only 15% of these are recovered for recycling. Less than 1% of material used to produce clothing is recycled into new clothing, representing a loss of more than USD 100 billion worth of materials each year.

WATER USAGE

The textile industry is one of the top 3 water wasting industries, and the 2nd largest polluter of freshwater resources on the planet. Textiles production uses around 93 billion cubic metres of water annually, contributing to problems in some water-scarce regions: 8,500 liters of water are needed to produce a pair of jeans and 2,600 to produce one single t-shirt.

TOXIC CHEMICALS & DYES

A quarter of the chemicals produced in the world are used in textiles. Unsafe use of agricultural chemicals has severe health impacts on workers in the field and on ecosystems that receive excess doses that runoff from farms. While there is little data on the volume of substances of concern used across the industry, it is recognised that textile production discharges high volumes of water containing hazardous chemicals into the environment. As an example, 20% of industrial water pollution globally is attributable to the dyeing and treatment of textiles.

SYNTHETIC FIBERS AND MICROPLASTICS

In order to get cheap prices, the industry has shifted to very cheap materials: synthetics. Primarily, polyester. Nearly 70 million barrels of oil are used each year to make the world’s polyester fiber, now the most commonly used fiber in our clothing. Taking more than 200 years to decompose.Today, polyester is in more than 50% clothing production. From 1980 to today, we have gone from producing 5 million metric tons of polyester to 70 million metric tons. Fast fashion is fueled by this disastrous material. A non-biodegradable, non-breathable, energy intensive fiber - identified as a major contributor to the issue of microplastics entering the ocean, which is a growing concern because of the associated negative environmental and health implications. It has been estimated that around half a million tonnes of plastic microfibres shed during the washing of plastic-based textiles such as polyester, nylon, or acrylic end up in the ocean annually.

REDESIGNING THE INDUSTRY

Upcycling is a philosophy and a design principle that includes 'recycling' but goes beyond this system by taking a 'whole system' approach to the vast flow of resources and waste through human society. It redesigns the current, one-way linear industrial system into a circular economy, and it is modeled on nature's successful strategies.

A circular system is restorative and regenerative by design, aiming to keep materials and components at their highest form of use and value at all times. It preserves and enhances natural resources, optimizes their yield, and minimizes system risks by managing renewable sources and flows. Existing materials are given more value, not less. A continuous positive design and development cycle, essential to minimize environmental impact and decrease the amount of waste that goes into landfills.

For every kilogram of upcycled textile waste, we save up to 20,000 liters of water.

For every ton of upcycled textiles, 20 tons of CO2 are prevented from entering the atmosphere.

Sustainable design has the power to eliminate the use of chemicals and dyes, as well as significant energy usage reduction.

Circular design and Upcycling is a powerful entry point into a critique of excessive consumption, waste, corporate irresponsibility, and the fundamental causes of environmental destruction.

UP - CY - CLE verb

Reuse (discarded objects or material) in such a way as to create a product of a higher quality or value than the original.

HISTORY

OUR STORY & WORK ETHIC

The New Denim Project is part of an industrial textile group, proudly operating since 1956 in Guatemala. Thanks to the efforts of various generations, we have continued to evolve until today in the manufacture of 100% sustainable eco-cotton yarn, fabrics, garments and accessories. The company's main objective has been to unite technology and ecology in the production of textiles in order to maintain our commitment to quality and remain environmentally responsible and competitive in the market.

Although our main focus has long been environmental responsibility, we believe social compliance is equally as important. Our workplace standards are 100% compliant to Guatemala’s local laws and regulations. We count with our own Code of Conduct since the founding of the company. At TND Textiles, we have a zero tolerance policy towards child labor, forced labor, discrimination, harassment and abuse. We are committed to providing an unconditionally healthy and secure work environment for all employees- as well as freedom of association and fair labor practices.

We are proud to join the #FashionRevolution movement- making every area of our operation completely transparent. Please follow us on social media to get to know and learn about the hands, minds and spirits behind all of our textile products.

TNDP TEXTILES

"The goal of upcycling is a delightfully diverse, safe, healthy, and just world with clean air, water, soil, and power—economically, equitably, ecologically, and elegantly enjoyed."

William Mc Donough

TEXTILES

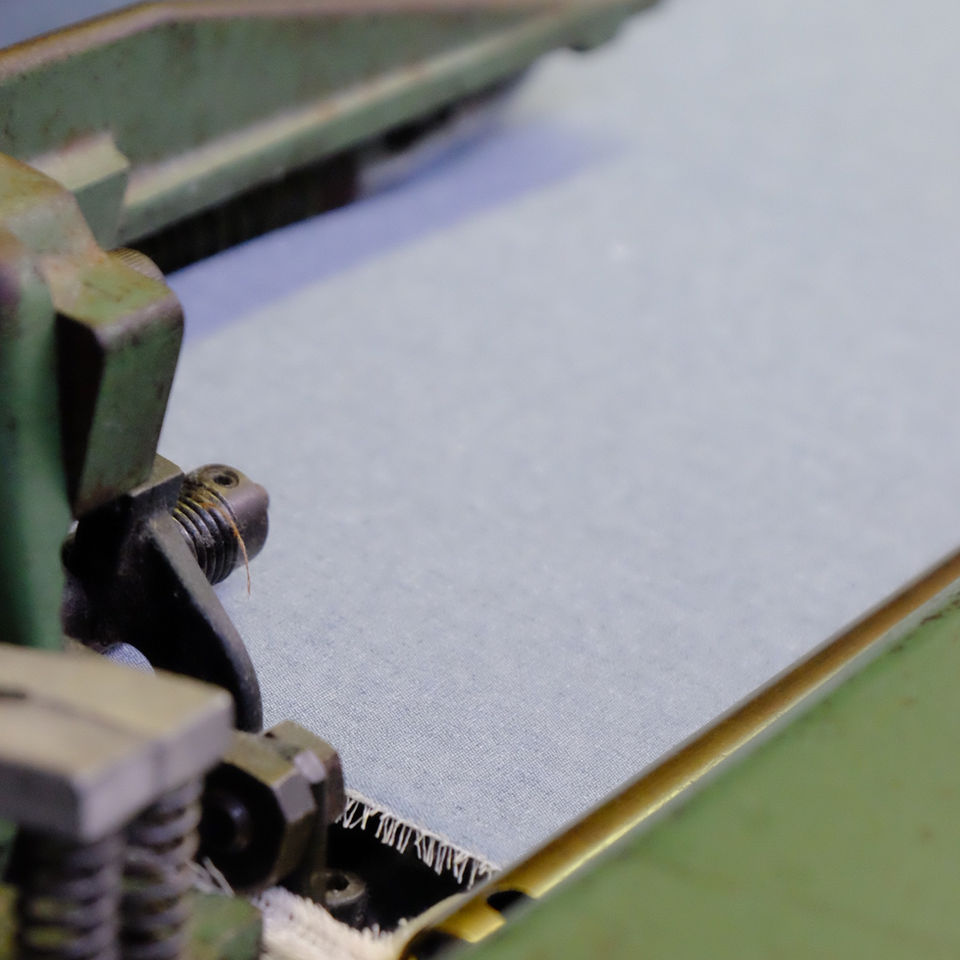

UPCYCLED / CHEMICAL-FREE / CIRCULAR / NATURAL FIBRES

CONTACT US TO INQUIRE ON OUR FULL TEXTILE COLLECTION, AND THE FOLLOWING SERVICES:

- Wovens custom design and patterns

- Full package service

- Handwoven fabrics

- Knit Fabrics

- Plied yarn

Specialty open-end yarns and woven fabrics. Raw material derived from upcycled cotton and post-industrial textile waste.

Our woven specialty textiles include the following: muslins, chambrays, twills, canvas, denim, oxford, selvedge denim, plain weave, gauzes, taffeta, flannels, plaids, home & kitchen textiles, upholstery, etc.

Woven fabrics weight ranges from ~ 2 oz up to 20 oz per sq m.

Yarn collection title ranges from a 4/1 Ne up to a 24/1 Ne.